Manual Wheelchair Design and Production

With permission from the World Health Authority we bring you part II of our series on increasing the quality and range of available wheelchairs in less resourced areas. In this edition we cover the four main principles of Manual Wheelchair Design and Production as follows:

- DESIGN Outlines methods for designing or selecting a manual wheelchair.

- PERFORMANCE Describes different types of wheelchair production, function and supply.

- EVALUATION Sets out the advantages and disadvantages of different wheelchair designs.

- DURABILITY Suggests how to evaluate wheelchairs in terms of performance, seating and postural support, as well as strength durability and safety.

Testimonial From Cambodia

In 1982 Tun “Reth” Channareth stepped on a landmine. He later had both of his legs amputated. Much of his family was killed by Pol Pot’s soldiers in the Vietnamese invasion of 1978. Forced to leave Phnom Penh with his remaining family in 1979 Reth received vocational training at a Thai refugee camp, where he stayed for 13 years.

In 1993, Reth moved back to Cambodia and was employed and trained as a wheelchair builder in a local wheelchair workshop. Reth himself received a three-wheeled active-style wheelchair and a tricycle through the workshop. The mobility provided by both the wheelchair and the tricycle has enabled Reth to work, care for his wife and six children, and become an active campaigner against landmines.

Reth is now an ambassador for the International Campaign to Ban Landmines (ICBL), an initiative he was co-awarded the Nobel Peace Prize for in 1997. He has travelled the world urging governments to make landmines history.

I have to admit that what happened to me, being a landmine victim, helped me realize that life does not end in one or more difficulties. Also, through the help of so many people around me I was able to go beyond the tragedy in my life. Now I am an active spokesperson for ICBL. Whenever there’s an opportunity to speak about advocacy to ban landmines, I make a sincere appeal to people and governments, asking them to support this campaign, to give more assistance to help the victims and their families. Also, at present I am working in the Jesuit Service Cambodia – Siem Reap team, in the wheelchair team and outreach programs. As of now, we are able to reach people in 222 villages, 90 communes and 12 districts. It is not an easy job for a double amputee, but I am happily fulfilled. – Reth

Wheelchairs Changing Lives

The purpose of these manual wheelchair design and production guidelines is to increase the quality and range of manual wheelchairs available in less-resourced settings, and where people simply cannot afford a wheelchair. Implementation of these guidelines aim to enrich the lives of wheelchair users in third world countries and lead to:

- A wider variety of wheelchair types and designs.

- Wheelchairs that are safe and meet minimum requirements.

- Lower long-term costs of wheelchairs.

- More available information about wheelchairs.

- National standards for wheelchairs.

These manual wheelchair design and production guidelines have been developed by the WHO (World Health Authority) to apply to manual wheelchairs with a variety of features. Including all levels of adjustability, three-and four-wheeled wheelchairs, folding and rigid wheelchairs, and adult and pediatric wheelchairs. While the guidelines are not written specifically for devices such as hand-powered tricycles, the principal recommendations may nevertheless be applicable. These guidelines can be used to design wheelchairs and select pre-existing wheelchair designs for production and supply to wheelchair services.

1: Wheelchair Design

1: Wheelchair Design

The objective of manual wheelchair design is to produce wheelchairs that perform well and can provide appropriate seating and postural support without compromising strength, durability and safety. This can be achieved when government authorities, manufacturers, engineers, designers, service providers and users fulfill their respective roles with respect to design.

It is recommended that government authorities develop and adopt national wheelchair standards applicable to all wheelchairs supplied in a country. This includes all locally produced wheelchairs and imported wheelchairs, whether donated or purchased.

The International Organization for Standardization (ISO) has developed international standards for wheelchairs, known as the ISO 7176 series. This series specifies a terminology and testing methods for evaluating wheelchair performance, size, strength, durability and safety. Many national standards committees have adopted the ISO 7176 series, or an individually tailored form of the series, as their own wheelchair standards.

All requirements in the ISO 7176 series may not reflect typical conditions in less-resourced settings, as some of the requirements were designed to simulate the conditions in city environments with smooth roads. When developing national standards, it is therefore important to consider environments, the weights and sizes of users, typical uses, and the available wheelchair and allied technologies (such as bicycle/tricycle) within the country.

Governments, manufacturers and suppliers need to work together to establish a sustainable supply of wheelchairs that meet national standards. Whether produced in the country or imported, it is important that the range of wheelchairs meets the diverse needs of users. Governments and organizations are encouraged to support manufacturers in using test equipment to improve the quality of their wheelchairs, to make efforts to minimize the costs of testing for local manufacturers, and to support the dissemination of wheelchair quality evaluations.

The resources needed to implement these guidelines can be minimized through joint planning and cooperation among government authorities, nongovernmental organizations, international nongovernmental organizations, disabled people’s organizations, foreign governments, bilateral aid agencies and the private sector. As much as possible, existing infrastructure and expertise should be used, supported and further developed.

Wheelchair Design Principles

Individuals ought to be trained to design, produce and test wheelchairs that meet these guidelines. This can be done by introducing these guidelines to students or practitioners of related disciplines.

Wheelchair evaluation and testing results should be recorded and made available to all stakeholders. Such information will help stakeholders to select the most appropriate wheelchair for a given use. Service providers, users and advocacy groups are also encouraged to use the information provided to communicate with wheelchair manufacturers and suppliers about their specific needs and how available wheelchairs meet their needs.

Stakeholders involved in the design and production of wheelchairs include purchasers, manufacturers, designers, evaluators and users. Experienced wheelchair users can often contribute substantially in designing wheelchairs. Key resources required to implement the design and production guidelines include:

- Engineers, designers, users, technicians and manufacturers.

- Facilities and equipment to produce or assemble wheelchairs.

- Facilities and equipment to evaluate wheelchairs.

- Product evaluators.

Wheelchair designs vary greatly to take account of the diverse needs of users. To ensure wheelchairs are appropriate, designers and providers must thoroughly understand the needs of the intended users and their environments. Users’ needs are best met when there is a variety of models from which to choose.

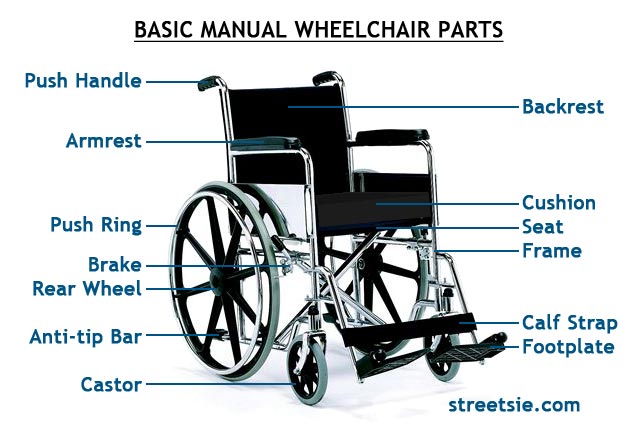

Basic Manual Wheelchair Parts

A cushion is to be considered an integral part of a wheelchair, and is therefore to be included with all wheelchairs. People with spinal cord injuries or similar conditions require pressure relief cushions that prevent the development of life-threatening pressure sores.

Wheelchairs should be designed to enable their users to participate in as many activities as possible. As a minimum, a wheelchair should enable the user to lead a more active life without having a negative effect on their health or safety. Comfort and safety are two important factors affecting the quality of life of long-term users.

The health and safety of users should never be compromised in order to reduce costs. Although it may seem that any wheelchair is better than no wheelchair, this is not true when the wheelchair causes or contributes to injury or other health risks. A wheelchair should be designed to ensure the user’s safety and health. There are many ways in which users can be injured by their own wheelchairs, as illustrated by the following examples:

- A wheelchair without a cushion or with an inadequate cushion can cause pressure sores. This in turn may require the user to spend many months in bed, without appropriate care and treatment this often leads to bedsores, secondary complications and even premature death.

- Unstable wheelchairs can tip and lead to users falling and injuring themselves.

- Wheelchairs that are too wide or are unduly heavy can cause shoulder injuries.

- Sharp edges on surfaces can cause cuts that in turn can lead to infection.

- Poor design can result in places on the wheelchair where the user or others can get their fingers or skin pinched.

- Wheelchairs that cannot endure daily use in the user’s environment may fail prematurely and can injure the user.

Wheelchairs used outdoors are subjected to greater wear and tear than those designed for indoor use or use on smooth roads and paths. A wheelchair must be strong enough not to suffer a sudden failure while being used. The wheelchair should be built to have the longest possible useful life and require the fewest repairs. A wheelchair should be designed so it can be repaired near the user’s home if it fails, and replacement parts should be easily available.

Wheelchairs should be appropriate for the environment in which they will be used and for the specific people who will use them. One wheelchair design will not suit everyone. When designing or selecting wheelchairs it is necessary to think about the environment and the way in which the wheelchair may be used.

When designing a new wheelchair, or selecting a pre-existing wheelchair design, it is important to know where the wheelchair will be produced. In different locations, the technical skills, available technology, materials and components available for production will vary. For this reason, a wheelchair designed for one region may not be suitable in another region. However, the fundamental design might be quite similar.

- Riding for long distances over rough roads.

- Going up and down many kerbs every day.

- Accessing built environments: narrow doorways, small turning areas, steep ramps, desks and tables, bathroom facilities (e.g. sitting and squatting toilets).

- Exposure to moisture such as rain, high humidity, snow, ice, hail and body fluids such as urine and sweat.

- User showering while sitting in the wheelchair.

- Exposure to extreme temperatures.

- User transporting goods on the push handles, upholstery, footrests or other parts of the wheelchair.

- Passengers riding on footrests and armrests.

- People lifting the wheelchair by one armrest, footrest or push handle when the wheelchair is occupied.

- Transporting the wheelchair in confined spaces or other cramped or crowded conditions.

The following categories can be used to describe and evaluate wheelchair designs.

- Functional performance, how a wheelchair performs for different users in different environments. The functional performance of a wheelchair is determined by its design and features.

- Seating and postural support, how a user’s body is supported by the wheelchair. This includes comfort and pressure relief.

- Strength, durability and safety, considers the safety of the user, the resistance to breaking and the durability of the wheelchair.

Wheelchair users are strongly encouraged to be involved in the design and selection process. From experience, users are the most knowledgeable about their own physical, social and cultural needs.

Wheelchair Design Criteria

1. Design brief. This is a written statement of the needs and criteria for the wheelchair. The criteria include environmental constraints (physical, cultural, social), local production resources, such as materials and human resources, performance requirements and target price. Design briefs should be developed in consultation with users and others familiar with the needs of intended users, and according to available resources. The design process can be an effective tool for selecting wheelchairs for large-scale provision to a region or for individual users.

2: Design/select wheelchair. After the design brief is written, design ideas are developed and prototypes are built and tested in the workshop. The process of designing, prototyping and testing may need to be repeated several times until the prototype meets the performance requirements of the brief. A design brief can also be helpful in selecting a wheelchair.

3: Product testing. When a prototype meets the performance criteria, it should be tested to ensure it meets strength and durability requirements. If the wheelchair fails the tests, the design may need to be changed.

4: User trials. Once the prototype has met all the performance, strength, durability and safety requirements, it should be tested by users who live in the environment the wheelchair is designed for. User trials allow for feedback from users, who are the most knowledgeable about the performance of the device.

5: Production and supply. If the user trials are successful, production and supply of the wheelchair may begin.

6: Long-term follow-up. At this point, long-term follow-up should be used to assess the performance of the wheelchair over time (for example, over several months). The feedback thus obtained should then be used to improve the design.

Wheelchairs may be produced nationally or imported. To provide a range of wheelchairs, some countries may choose to support both national production and importation. Each supply method has an appropriate application. With many different needs within a region, a variety of supply methods may be suitable, the long-term goal being sustainable solution.

It is recommended that all wheelchairs, irrespective of supply method, meet or exceed national wheelchair standards and be repairable locally. When determining whether to acquire wheelchairs via import or local production, decision-makers are advised to balance a variety of factors. These include:

- The needs of local wheelchair users.

- The quality and variety of wheelchair models.

- The long-term reliability of supply of wheelchairs and spare parts.

- The possibility of influencing the design, features, materials, etc.

- The purchase price.

- The cost of repair and replacement.

- The effect on local employment and wheelchair production.

- Coordination of supply with an overall plan for wheelchair provision.

- The amount and term of the funding available.

- Policies and strategies, including long-term sustainability.

2: Wheelchair Performance

2: Wheelchair Performance

Functional performance is how a wheelchair performs for different users in different environments. The functional performance of a wheelchair is determined by its unique design and features. There are many compromises to consider when designing or selecting for different uses. This section provides information on the key features of a wheelchair that affects the main categories of performance and how to evaluate them. It also outlines compromises that need to be considered when choosing different design features.

To meet the functional performance needs of individual users, a range of wheelchair designs and sizes are needed. Wheelchair stability affects how safe the wheelchair is, and how well the user can carry out activities in the wheelchair. Wheelchair tipping causes many injuries for users.

Static stability relates to the stability of the wheelchair when it is not moving. This determine whether the wheelchair will tip over (where some wheels lose contact with the ground) when the user, for example, leans over to pick something up off of the ground or transfers into or out of his or her wheelchair.

Dynamic stability relates to the stability of the wheelchair when moving. This determines whether the user can ride over bumps or sloped surfaces without tipping. The design features used to increase wheelchair stability have secondary effects on other functional performance characteristics. For example, moving the front castor wheel forward increases stability but reduces the maneuverability of the wheelchair in confined spaces. Apart from seat height, stability in each direction is sensitive to several design factors.

Rearward stability (resistance to tipping backwards) is affected by the rear axle position in relation to the user’s centre of gravity. Increasing rearward stability has associated advantages and disadvantages. For example, anti-tip devices can be useful for some users who are unstable or are learning to perform “wheelies” (whereby the user raises the front castor wheels and balances on the rear drive wheels). However most anti-tip designs restrict the wheelchair’s ability to travel over uneven surfaces (such as kerbs or dips).

Forward stability is affected by the size and position of the front castor wheel in relation to the user’s centre of gravity. A good example increasing forward stability and the associated advantages and disadvantages is large front castor wheels. Front castor size significantly affects dynamic stability, with larger front wheels the wheelchair will be able to roll over larger obstacles without being stopped and tipped forward. Although larger front castor wheels need more room to swivel so the wheelchair design will need to be much longer or wider to allow room for the user’s feet.

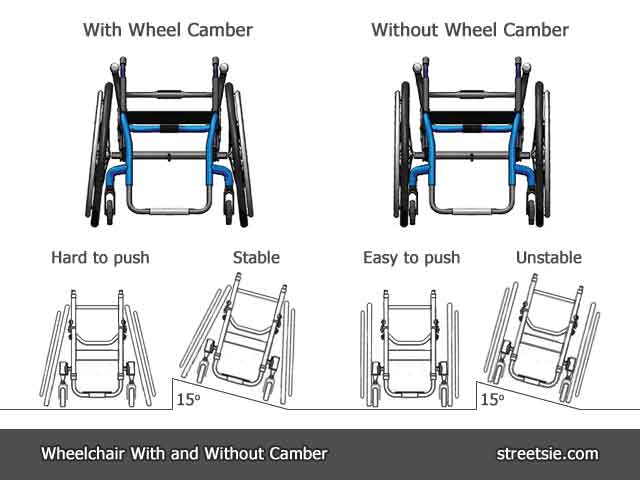

Sideways stability is affected by wheelchair width. The further out to the side of the wheelchair the front and rear wheels touch the ground, the more the chair will resist tipping over sideways. Consequently of disadvantage a wide wheelchair is more difficult to get through narrow doorways. Camber also increases the width of the wheelchair when it is folded.

Paraplegic wheelchair users with advanced mobility skills and good trunk control can partially compensate for some of the wheelchair’s instability if they can balance on the rear wheels (perform a wheelie) and if they can shift their weight forwards, backwards or to the side to prevent tipping. The fact that quadriplegics (tetraplegics) have very limited to no balance must also be taken into consideration. Increasing the camber on rear wheels makes a wheelchair more stable but also harder to push.

Maneuverability around obstacles determines the user’s ability to maneuver in an environment with confined spaces, such as a toilet with a narrow door and very limited space.

Moving through narrow passageways the narrowest space through which a wheelchair can pass is determined by its width, measured from the outermost point on each side. The ability to move through narrow passageways can be improved by making the wheelchair narrower.

Pulling up close to surfaces and objects how close users can get to surfaces and objects they cannot roll under, such as toilets, low tables, counter tops, centre-post tables and bathtubs, is determined by how far the wheelchair extends both forwards and to the side of the seat. A user can get closer to surfaces and objects if the wheelchair is shorter in height.

Rolling under surfaces where the user’s ability to pull up to a table is determined by the height of the user’s knees (the length of the user’s lower leg plus the minimum safe height of the footrest above the ground). Some types of fixed armrest also prevent users from pulling up to tables and counters.

Turning around in confined spaces where the smallest area in which a wheelchair can turn around is determined by its maximum diagonal measurement.

Maneuverability over obstacles determines the user’s ability to negotiate obstacles such as soft ground or raised obstacles. When negotiating obstacles, the user is at risk of tipping backwards or forwards and falling out of the chair (a common cause of injury); thus it is also important to consider stability when evaluating a wheelchair’s ability to maneuver over obstacles.

Maneuvering over soft ground such as mud, sand, grass, gravel and snow, depends on the area of contact that the wheels have with the ground and the amount of weight on the wheel. There are many ways of improving maneuverability over soft ground each with their associated advantages and disadvantages.

Maneuvering over raised obstacles such as bumps, kerbs or rocks, depends on many factors. The size of the castor wheel, the distance of the castor wheel from the user’s centre of gravity and the springiness of the castor wheel, all have a significant effect. Castor flutter is also a result of hitting bumps at speed.

Pushing efficiency is related to the amount of energy required for the user to push the wheelchair over a given distance. Lighter wheelchairs are normally easier to push, but there are many factors and wheelchair features that affect how difficult or easy it is to push one’s wheelchair. A wheelchair with a broken or misaligned component (e.g. untrue wheels, distorted frame, broken bearings causing friction, unparallel wheels or poorly inflated pneumatic tyres) resists the user’s forward motion, thereby wasting much of the user’s pushing energy.

Ability to transfer into and out of the wheelchair depends on the type of transferral that is easiest for the user and whether the wheelchair’s structure impedes transferral. For users who transfer by pivoting their bottom about their knees (side transfer), there must be sufficient space at the end of the seat surface to be able to move their body past the armrest. Removable armrests are an advantage when transferring but consider the disadvantage of removable armrests being lost or damaged.

Transporting the wheelchair for long-distance travel by, for example, bus, taxi or train, take into account of the design and size of the wheelchair and the materials used in its construction. Weight is a crucial factor in transporting a wheelchair, and weight is determined by the types of component (wheels/frames) used and by the construction materials (e.g. steel, steel/aluminum alloy or other metal). Reducing weight has a direct effect on durability and cost. Design and size are equally important, foldable and smaller wheelchairs being easier to carry.

Wheelchairs that can break down (pull apart) are easier to lift and transport however removable parts can get lost, bent or broken. Standard push-button quick-release axles (rear wheels) are convenient to transport but are not available everywhere, they are more expensive than fixed axles, and have a shorter life where conditions of use are rough. Of further disadvantage, sand, dust and moisture can cause the locking mechanism to seize. This may cause the axle to slip out of the axle socket resulting in the wheel to falling off the wheelchair and injury.

Reliability of a wheelchair is determined by its durability and the length of its useful life. In the case of failure, the frequency and difficulty of repair also determines the reliability of a particular model of wheelchair. Ways of improving the reliability of a wheelchair include:

- Better materials and technologies at an affordable cost.

- Fewer removable parts.

- Non-folding design where folding is not a necessity.

- Use of materials that can be repaired or replaced locally.

- Regular servicing, repair and maintenance.

- Knowledge by the user of the product and its use, care and maintenance.

3: Wheelchair Evaluation

3: Wheelchair Evaluation

It is recommended that a wheelchair be evaluated based on the functional performance measures and that the results be available to the users and purchasers. The functional performance areas in which a wheelchair should be evaluated or reported on are:

- Static stability.

- Dynamic stability.

- Rolling resistance.

- Ability to repair/availability of components.

- Overall dimensions, mass and turning space.

Static stability and overall dimensions, mass and turning space tests and reporting techniques are covered in ISO standards 7176-1, 7176-5 and 7176-7.

An appropriate wheelchair will establish a balance between adequate seating and postural support as well as mobility. Good postural support is important for everyone, especially for people who have an unstable spine or are likely to develop secondary deformities like scoliosis (curvature of the spine). The significance of good seating and postural support can mean the difference between the user being active and an independent member of society and the user being completely dependent and at risk of serious injury or even death.

All body contact surfaces provide seating and postural support. Together, these parts of the wheelchair help the user to maintain a comfortable and functional posture and to provide pressure relief. This is very important for spinal cord injury wheelchair users with paralysis and other problems with skin sensation.

As a basic guide to the design and selection of wheelchairs we don’t cover in detail specific wheelchairs that provide a high level of adjustability or custom adaptations for high level tetraplegics with spinal cord injury who require complex postural support. That said, any wheelchair and cushion should meet the seating and postural support requirements of the user(s) including the size of the wheelchair, the type of cushion, and the adjustability and ergonomic factors of the wheelchair.

Wheelchairs should be provided with a cushion that is appropriate to manage the user’s risk of developing pressure sores. A wheelchair should be evaluated based on the seating and postural support measures, and the results should be available to the users and purchasers. Cushions should be evaluated and rated based on their ability to provide comfort, pressure relief and postural support, and the results should be made available to the users and purchasers.

Cushions Slings And Solid Seats

The two most common types of seat base are “sling seats” and “solid seats”. Sling seats (also known as slung seats) are made of a flexible material such as canvas or vinyl. Solid seats are not flexible and are often made of wood, metal plate or plastic.

Failure of the wheelchair seat and the cushion is a common problem. Sling seats made of poor quality or inappropriate materials can quickly stretch, sag and tear. Wheelchair cushions are not designed to work on such seats made of poor quality or inappropriate materials. This means that the user ends up sitting on an unstable seat without pressure relief. The result can be that the user will develop pressure sores or stop using the wheelchair owing to discomfort.

Some design solutions include tension-adjustable sling seats made with straps and stretch-resistant fabric and pressure-relief cushions for wheelchairs with sling seats provided with a contoured bottom surface to accommodate the curve of the sling. Many cushions can easily be modified for use on a sling seat by cutting off the lower, outer edge from front to back on each side to accommodate the seat rail and the curve of the sling.

- Wheelchair seats should have a continuous surface with no breaks that might cut or pinch the user’s skin.

- The angle of the seat, in relation to the horizontal, should be between 0 and 12 degrees (with the front portion of the seat higher than the rear portion of the seat).

- The seat must be level from side to side.

- A range of seat sizes should be available to fit a range of body sizes.

- Sling seats should be designed with materials that do not stretch over time from the weight of the user.

- Sling seats and solid seats should be used with cushions designed or modified for use on a sling seat and solid seat respectively.

An inadequate pressure-relief cushion is the one component of a wheelchair that is most likely to cause pressure sores, serious injury or premature death. Wheelchair cushions are used for three reasons: comfort, pressure relief and postural support. For many users, a cushion that provides some comfort will help them to use the wheelchair for a longer time.

Spinal cord injury users with limited or no skin sensation are always at risk of developing pressure sores when using a wheelchair without a proper cushion. These users must use a pressure relief cushion to help reduce this risk and maintain a healthy lifestyle.

Many users require some adaptations or modifications to their cushion to help provide additional postural support or pressure relief. Wheelchair manufacturers need to either keep a good stock of different types and sizes of cushion or have the capacity to produce and modify a cushion as and when needed.

- The cushion should be removable from the wheelchair.

- The cushion should be easy to clean using basic materials such as soap and water.

- The cushion should be an appropriate size to fit on the seat base.

- Correct cushion use and the way in which it should be placed on the wheelchair seat (which side is up, and which is the front of the seat) should be clearly indicated.

- A pressure relief cushion should reduce pressures at the high-risk areas for pressure sore development (commonly at ischial tuberosities and sacrum).

- A pressure relief cushion should minimize the build-up of moisture between the cushion and the user’s skin.

- Information should be available on how to use the cushion, how to maintain it, the expected life of the cushion, when to replace the cushion or parts of it, and any particular risks when using the cushion.

- The cushion and cushion cover material should not cause high pressures, thereby reducing the effectiveness of the cushion in distributing pressure over the seat surface.

- Pressure relief cushions should maintain their pressure relief properties in the climates where the cushion is expected to be used.

It is recommended that wheelchairs and cushions be evaluated based on the seating and postural support performance measures, and the results be available to the users and purchasers. The areas in which a wheelchair and cushion should be evaluated or reported on are, seating dimensions and adjustability plus cushion type and characteristics. Seating dimensions and cushion characteristics tests and reporting techniques are covered in ISO standards 7176-7 and 16840-2.

Backrest

The backrest provides users the necessary postural support. It needs to be of different heights but usually available in two sizes. Some users require more support from a backrest than others. For some users, a high backrest can reduce their ability to propel themselves effectively. Backrests may be sling or solid types with foam cushioning and upholstery.

- The angle between the seat and the backrest (seat to back angle) should be between 80 and 100 degrees.

- Different backrest heights should be available.

- The backrest should support the normal curvature of the spine.

- The middle of the back should be able to rest further back than the back of the pelvis.

Footrests

The footrest provides users with support for their feet and legs. Footrests must be individually adjusted for each user. Correctly adjusted, the footplate reduces pressure on the user’s seat and puts the user in a healthy sitting posture. Footrests may also include a calf strap and/or toe loops to keep the foot on the footplate.

Footrests need to be long or wide enough to support the foot but, at the same time, should not create difficulty while folding or moving around. Sufficient ground clearance needs to be maintained to prevent the footrest hitting obstacles or catching and tipping the wheelchair on uneven ground. The height of the footrest should be adjustable.

Armrests

Manual wheelchair armrests are only intended for temporary postural support. If needed, other postural support options should be used to keep the user’s arms free for activities such as propelling. Armrests assist in frequent pressure relief lifts and transferring into and out of the wheelchair, for example by pushing down on the armrest to lift buttocks.

Many users find it easier to transfer into and out of their wheelchair if the armrests are “low-profile” (closely following the profile of the rear wheel) or removable. In other words, armrests should be removable, folding or low-profile for easy transferral in and out of the wheelchair.

The rear wheel should be in a position that allows the user to have the best push stroke as possible and keeps the user safely balanced according to his or her skill level and ability. The position of the rear wheel should allow the user to have a good push stroke and provide the necessary stability.

4: Wheelchair Durability

4: Wheelchair Durability

The goal of this section is to help define what makes a safe and reliable wheelchair, and how to evaluate and report these attributes to stakeholders. When a wheelchair fails, the user is not only at risk of injury but may not be able to go anywhere or do anything until the wheelchair is repaired or replaced.

Safe And Reliable Wheelchairs

Apart from ensuring that the wheelchair is safe and effective, evaluating strength and durability is a way of gathering important information that can be useful for all stakeholders – users, designers, providers, manufacturers and funding agencies. Keeping accurate records of the results of strength and durability tests will help wheelchair designs evolve so that their quality and effectiveness continually improve.

- All wheelchairs should meet the strength, durability and safety requirements of user(s) in their own environment(s).

- It is recommended that each country develop its own wheelchair standards to ensure a reasonable quality, for instance by using the ISO 7176 series of standards as a basis. When developing national standards, it is important to consider the weights and sizes of the users, typical use, available testing equipment and available wheelchair technology. The standards should be available to manufacturers, purchasers and users, and be reviewed from time to time.

- All wheelchairs should be evaluated based on the strength, durability and safety requirements set by the country, and the results should be available to users and purchasers.

A wheelchair should be strong and durable enough to withstand the wear and tear placed on it by the user and to keep the user safe. Wear and tear consists of:

- Static forces.

- Impacts.

- Fatigue stresses from use over time.

Simple testing can be developed to ensure strength and durability. The flammability of the wheelchair, the effectiveness of the brakes and the safety of the surfaces on the wheelchair also affect the safety of the user.

Armrests

- Should be removable with a reasonable amount of force.

- Should not break or bend under the user’s body weight.

- Should not break or bend when used to lift user and wheelchair.

Backrests

- Should not break or bend during transfers or while riding on uneven terrain.

Brakes

- Should stop a wheelchair from sliding when on an incline.

- Should not suddenly release while in use.

Castor Assembly

- Castor should not fail when the castor wheel hits an object (e.g. a curb).

Footrests

- Should fold with a reasonable amount of force.

- Should not break or bend when used to lift user and wheelchair.

- Should not break or bend when additional passengers or packages are loaded.

- Should not break or bend when hitting an object such as a wall or curb.

Frames

- Should not break or bend when used on uneven terrain.

Push Handles

- Should not break or bend when used to lift user and wheelchair.

- Handgrip should not slide off of push handle when user is being assisted up stairs or curb.

Rear Wheels And Axles

- Wheels or axles should not break or bend when user goes over a normal kerb.

- Wheels, axles and wheel-mounting hardware should not fail when user drops off kerb at angle.

- Axles or wheel-mounting hardware should not break or bend when under typical forces.

- Wheel spokes should not rattle or become loose.

General

- Surfaces should not have sharp edges, sharp points or pinch points.

- Wheelchair should not be flammable, i.e. easily combustible materials should not be used.

- Wheelchairs should be equipped with front and rear reflecting stickers or signs for increased road safety.

- Tipping levers should not break when assistant uses levers to tip user back.

- Hand rim should not break or bend when it hits an object.

- Wheelchair should not break when it falls or is dropped by handler loading or unloading it from bus or car.

- Wheelchair should not break in normal use.

It is recommended that a wheelchair be evaluated based on the strength, durability and safety requirements, and the results be available to the users and purchasers. Static strength, impact resistance, durability and brake effectiveness tests and reporting techniques are covered in ISO standards 7176-8, 7176-3 and 7176-16.

National Testing

It is recommended that testing according to national wheelchair standards be made easily accessible to all manufacturers and providers. One method for making testing accessible is to use testing methods that are simple and inexpensive.

Fatigue Testing

Fatigue testing is critical for ensuring the reliability and safety of a wheelchair. Where fatigue testing is not possible, it is especially important to carry out well-monitored user trials and long-term follow-up to evaluate safety, reliability and durability.

Even those who do perform fatigue testing need to be aware that the testing equipment and prescribed cycles of the standards do not necessarily reflect the actual loads the wheelchair will endure over its lifetime. Monitoring the use of the wheelchair in the field will help to determine the durability and performance of the wheelchair over time.

Environmental Testing

Workshop testing does not subject wheelchairs to environmental conditions that they typically endure. Many wheelchairs fail as a consequence of dirty or worn bearings, rusty bolts or frames, etc. Therefore, long-term follow-up of users is of great importance.

User Trials

User trials are performed after workshop tests to provide feedback about the durability, effectiveness and functional performance of a wheelchair in the context and environment in which it will be used. User trials involve the selection of users who agree to use pre-production or pre-distribution wheelchairs over a given period of time. The users provide feedback at set intervals during the trial, answering specific questions about the wheelchair’s performance. Focus groups can also be used to ensure as much feedback is gained as possible.

If user trials reveal that failures are likely to occur, then design changes should be made or a different wheelchair should be found, and testing should begin again. In the case of production, if significant design changes are called for, strength and durability testing should be performed again, followed by more user trials. If only minor changes are called for, then it may be appropriate to skip the strength and durability testing and perform the user trials again.

Long-term Follow-up

After workshop and user trial testing has proven the wheelchair design is safe and effective, the wheelchair will be put into production and then sent to wheelchair services for provision. A sample of wheelchairs should be followed over time. This could be done, for instance, by contacting selected users six months, one year and three years after they received the wheelchair to determine the typical failures and maintenance requirements and their general opinion on the functional performance of the wheelchair.

Conclusions

Governments are recommended to develop and adopt national wheelchair standards to ensure a reasonable quality of wheelchairs, for instance by using the ISO 7176 series of wheelchair standards as a basis.

It is recommended that the national wheelchair standards are applicable to all wheelchairs supplied in a country, whether produced within the country or imported. General design considerations include user health and safety, strength and durability, suitability for use and production methods.

Wheelchair designs should be evaluated in three main areas: functional performance; seating and postural support; and strength, durability and safety. Results of the evaluation and testing of wheelchairs must be available to users and purchasers.

A variety of factors need to be considered when determining whether wheelchairs should be acquired through national production or importation. Wheelchairs and spare parts need to be available, accessible and affordable.

Wheelchairs should be tested by users in the context and environment in which they will be used, before they are supplied to services or users (before production or before large-scale purchase). Long-term follow-up studies should be used to ensure the wheelchair is safe and effective over longer periods of use.

Resources

- ISO 7176-24:2004. Wheelchairs – Part 24: Requirements and test methods for user-operated stair-climbing devices. Geneva, International Organization for Standardization, 2004 http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=31276, accessed 9 March 2008.

- Chan SC, Chan AP. User satisfaction, community participation and quality of life among Chinese wheelchair users with spinal cord injury: a preliminary study. Occupational Therapy International, 2007, 14:123–143.

- Krizack, M. The importance of user choice for cost-effective wheelchair provision in low-income countries. In: Proceedings, 12th World Congress of the International Society for Prosthetics and Orthotics, Vancouver, 29 July – 3 August 2007. Copenhagen, International Society for Prosthetics and Orthotics, 2007.

- Kirby RL, Ackroyd-Stolarz SA.Wheelchair safety – adverse reports to the United States Food and Drug Administration. American Journal of Physical Medicine & Rehabilitation, 1995, 74:308–312.

- ISO 7176-7:1998. Wheelchairs – Part 7: Measurement of seating and wheel dimensions. Geneva, International Organization for Standardization, 1998 http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=13783, accessed 9 March 2008.

- ISO 7176-8:1998. Wheelchairs – Part 8: Requirements and test methods for static, impact and fatigue strengths. Geneva, International Organization for Standardization, 1998 http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=13784, accessed 9 March 2008.

- Armstrong W et al. Evaluation of CIR-Whirlwind Wheelchair and service provision in Afghanistan. Disability and Rehabilitation, 2007, 29:935–948.

- Pearlman J et al. Lower-limb prostheses and wheelchairs in low-income countries: an overview. IEEE Engineering in Medicine and Biology Magazine, 2008 (in press).

- Reisinger KD et al. Whirlwind Wheelchair in Afghanistan: nine-month follow-up. In: Proceedings, 12th World Congress of the International Society for Prosthetics and Orthotics, Vancouver, 29 July – 3 August 2007. Copenhagen, International Society for Prosthetics and Orthotics, 2007.

- World Health Organization, Guidelines on the provision of manual wheelchairs in less-resourced settings. 2. Wheelchairs – supply and distribution, 2008.

I have a new wheel design that offers superior hand grip area, lower weight, higher strength and lower overall cost. I don’t know very much about the wheel chair industry and would like discuss my design with someone who buys high performance wheels for wheel chair manufacturers.

email (contact info removed by admin) Peter Neuer, thanks

very good wheelchair

if you want your wheelchair to be easier to push get size 28in rear tires(basketball tires im told) theres more push area to one push.

So detailed tutorial, one of the best articles on wheelchairs and thir construction and usage. Thanks.

In a standard wheel chair a demented person who shuffles about

constantly runs over her own feet with the small front wheels.

Is there a design or chair modification to prevent this problem?

Many dementias coming. Smart designer needed NOW.

My name is Keith Richardson. An inventor colleague( former aircraft design engineer) has built an ingenious prototype adaption for a standard wheelchair that enables those with limited hand grip ( through injury or disabilty) and not able to use the wheel chair wheel rails effectively, to manoeuvre and propel a wheelchair easily.. The prototype was used very successfully and enthusiastically by an 88 year old man ( for whom it was designed) over a number of years. We wish to make this design widely available ….can anyone advise on possible organisations or manufacturers who may be interested to trial and manufacture the adaption kit? Please contact me Keithenglish17@gmail.com mob UK 07729678418

I am getting a new manual wheelchair and I live in a very hot climate where the canvas back is no good, I have been trying to get the wheelchair sales people to try and get me a mesh back for my wheelchair as the canvas one is agony for my back and is sore all the time.